Residual-current device

A residual-current device (RCD), similar to a Residual Current Circuit Breaker (RCCB), is an electrical wiring device that disconnects a circuit whenever it detects that the electric current is not balanced between the energized conductor and the return neutral conductor. Such an imbalance is sometimes caused by current leakage through the body of a person who is grounded and accidentally touching the energized part of the circuit. A lethal shock can result from these conditions. RCDs are designed to disconnect quickly enough to mitigate the harm caused by such shocks although they are not intended to provide protection against overload or short-circuit conditions.

In the United States and Canada, a residual current device is also known as a ground fault circuit interrupter (GFCI), ground fault interrupter (GFI) or an appliance leakage current interrupter (ALCI). In Australia they are sometimes known as "safety switches" or simply "RCD" and in the United Kingdom they can be referred to as "trips" or "trip switches". They can be found in kitchens, bathrooms, and other places that can be wet.

Contents |

Purpose and operation

1. Electromagnet with help electronics

2. Current transformer secondary winding

3. Transformer core

4. Test switch

L live conductor

N neutral conductor.

RCDs are designed to prevent electrocution by detecting the leakage current, which can be far smaller (typically 5–30 milliamperes) than the currents needed to operate conventional circuit breakers or fuses (several amperes). RCDs are intended to operate within 25-40 milliseconds, before electric shock can drive the heart into ventricular fibrillation, the most common cause of death through electric shock.

In the United States, the National Electrical Code requires GFCI devices intended to protect people to interrupt the circuit if the leakage current exceeds a range of 4–6 mA of current (the trip setting is typically 5 mA) within 25 ms. A GFCI device which protects equipment (not people) is allowed to trip as high as 30 mA of current; this is known as an Equipment Protective Device (EPD). In Europe, the commonly used RCDs have trip currents of 10–300 mA.

RCDs operate by measuring the current balance between two conductors using a differential current transformer. This measures the difference between the current flowing out the live conductor and that returning through the neutral conductor. If these do not sum to zero, there is a leakage of current to somewhere else (to earth/ground, or to another circuit), and the device will open its contacts.

Residual current detection is complementary to over-current detection. Residual current detection cannot provide protection for overload or short-circuit currents.

RCDs with trip currents as high as 500 mA are sometimes deployed in environments (such as computing centers) where a lower threshold would carry an unacceptable risk of accidental trips. These high-current RCDs serve more as an additional fire-safety protection than as an effective protection against the risks of electrical shocks.

In some countries, two-wire (ungrounded) outlets may be replaced with three-wire GFCIs to protect against electrocution, and a grounding wire does not need to be supplied to that GFCI, but the outlet must be labeled as such. The GFCI manufacturers provide tags for the appropriate installation description.

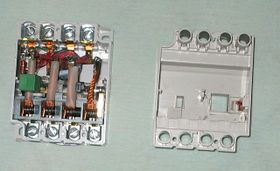

Example

The photograph depicts the internal mechanism of a residual current device (RCD). The device pictured is designed to be wired in-line in an appliance power cord. It is rated to carry a maximum current of 13 amperes and is designed to trip on a leakage current of 30 mA. This is an active RCD; that is, it doesn't latch mechanically and therefore trips out on power failure, a useful feature for equipment that could be dangerous on unexpected re-energisation.

The incoming supply and the neutral conductors are connected to the terminals at (1) and the outgoing load conductors are connected to the terminals at (2). The earth conductor (not shown) is connected through from supply to load uninterrupted.

When the reset button (3) is pressed the contacts ((4) and hidden behind (5)) close, allowing current to pass. The solenoid (5) keeps the contacts closed when the reset button is released.

The sense coil (6) is a differential current transformer which surrounds (but is not electrically connected to) the live and neutral conductors. In normal operation, all the current down the live conductor returns up the neutral conductor. The currents in the two conductors are therefore equal and opposite and cancel each other out.

Any fault to earth (for example caused by a person touching a live component in the attached appliance) causes some of the current to take a different return path which means there is an imbalance (difference) in the current in the two conductors (single phase case), or, more generally, a nonzero sum of currents from among various conductors (for example, three phase conductors and one neutral conductor).

This difference causes a current in the sense coil (6) which is picked up by the sense circuitry (7). The sense circuitry then removes power from the solenoid (5) and the contacts (4) are forced apart by a spring, cutting off the electricity supply to the appliance.

The device is designed so that the current is interrupted in a fraction of a second, greatly reducing the chances of a dangerous electric shock being received.

The test button (8) allows the correct operation of the device to be verified by passing a small current through the orange test wire (9). This simulates a fault by creating an imbalance in the sense coil. If the RCD does not trip when this button is pressed then the device must be replaced.

Three-phase example

For a three-phase variant all live conductors and the neutral must pass through the current transformer.

Rules and regulations

Rules and regulations differ widely from country to country. In Europe, the UK has only mandated the use of RCDs in new installations since July 2008. In contrast, Germany requires the use of RCDs on all sockets up to 20A which are for general use. This rule was introduced in June 2007 (DIN VDE 0100-410 Nr. 411.3.3). In Norway, it has been required in all new homes since 2002, and on all new sockets since 2006. In Australia, they have been mandatory in all new houses since 1991 on all power and lighting circuits.. In the U.S., the National Electrical Code requires GFCIs for underwater swimming pool lights (1968); construction sites (1974); bathrooms and outdoor areas (1975); garages (1978); near hot tubs or spas (1981); hotel bathrooms (1984); kitchen counter receptacles (1987, revised 1996 and specifically excluding the refrigerator outlet, which is usually on a dedicated circuit); crawl spaces and unfinished basements (1990); wet bar sinks (1993); laundry sinks (2005).[1]

Use and placement

In most countries, not all circuits in a home are protected by RCDs. If a single RCD is installed for an entire electrical installation, any fault will cut all power to the premises. Normal practice in domestic installations in the UK was to use a single RCD for all RCD protected circuits but to have some circuits that are not protected at all (sockets usually are on the RCD; lamp holders usually aren't; other circuits vary by who installed the system). Regulation introduced in 2008 dictate that on all new electrical installations in the UK, all circuits must be protected by an RCD ; however, this does not affect existing installations.

GFI receptacles in the USA have connections to protect downstream receptacles so that all outlets on a circuit may be protected by one GFI outlet.

Residual current and overcurrent protection may be combined in one device for installation into the service panel; this device is known as a GFCI breaker in the US and as an RCBO in Europe. In the US, RCBOs are more expensive than RCD outlets.

More than one RCD feeding another is unnecessary, provided they have been wired properly. One exception is the case of a TT earthing system where the earth loop impedance may be high, meaning that a ground fault might not cause sufficient current to trip an ordinary circuit breaker or fuse. In this case a special 100 mA (or greater) trip current time-delayed RCD is installed covering the whole installation and then more sensitive RCDs should be installed downstream of it for sockets and other circuits which are considered high risk.

Testing

RCDs can be tested with the built-in test button to confirm functionality on a regular basis. RCDs if wired improperly may not operate correctly and are generally tested by the installer to verify correct operation. Use of a solenoid voltmeter from live to earth provides an external path and can test the wiring to the RCD. Such a test may be performed on installation of the device and at any "downstream" outlet.

Limitations

A residual current circuit breaker cannot remove all risk of electric shock or fire. In particular, an RCD alone will not detect overload conditions, phase to neutral short circuits or phase-to-phase short circuits. Over-current protection (fuse or circuit breaker) must be provided. Circuit breakers that combine the functions of an RCD with overcurrent protection respond to both types of fault. These are known as RCBOs, and are available in 1, 2, 3 and 4 pole configurations. RCBOs will typically have separate circuits for detecting current imbalance and for overload current but will have a common interrupting mechanism.

An RCD will help to protect against electric shock where current flows through a person from a phase (live / line / hot) to earth. It cannot protect against electric shock where current flows through a person from phase to neutral or phase to phase, for example where a finger touches both live and neutral contacts in a light fitting; a device can not differentiate between current flow through an intended load from flow through a person.

Whole installations on a single RCD, common in the UK, are prone to nuisance trips that can cause safety problems with loss of lighting and defrosting of food. RCDs also cause nuisance trips with appliances where earth leakage is common and not a cause of injury or mortality, such as water heaters.

A dangerous condition can arise if the neutral wire is broken or switched off before the RCD while its live wire is not interrupted. In this situation the tripping circuitry of the RCD that needs power to be supplied will cease to work. The circuit will look like it is switched off, but if someone touches the live wire thinking that it is de-energized, the RCD will not trip. For this reason circuit breakers must be installed in a way that ensures that the neutral wire is turned off only at the moment when the live wire is also turned off. Separate single-pole circuit breakers must never be used for live and neutral, only two or four pole breakers must be used in cases there is a need for switching off the neutral wire.

History and nomenclature

The world’s first high-sensitivity earth leakage protection system (ie. a system capable of protecting people from the hazards of direct contact between a live conductor and earth), was a second-harmonic magnetic amplifier core-balance system, known as the magamp, developed in South Africa by Henri Rubin. Electrical hazards were of great concern in South African gold mines, and Rubin, an engineer at the company F.W.J. Electrical Industries, developed a cold-cathode system in 1955 which operated at 525 V and had a tripping sensitivity of 250 mA. Prior to this, core balance earth leakage protection systems operated at sensitivities of about 10 A.

The cold cathode system was installed in a number of gold mines and worked reliably. However, Rubin continued working on improving sensitivity, and by early 1956, he had produced a prototype second-harmonic magnetic amplifier-type core balance system (South African Patent No. 2268/56 and Australian Patent No. 218360). The prototype magamp was rated at 220V 60A and had an internally adjustable tripping sensitivity of 12.5 to 17.5 mA. Very rapid tripping times were achieved through a novel design, and this combined with the high sensitivity was well within the safe current-time envelope for ventricular fibrillation determined by Charles Dalziel of the University of California, Berkeley, USA, who had estimated electrical shock hazards in humans. This system, with its associated circuit breaker, included overcurrent and short-circuit protection. In addition, the original prototype was able to trip at a lower sensitivity in the presence of an interrupted neutral, thus protecting against an important cause of electrical fire.

Following the accidental electrocution of a woman in a domestic accident at the Stilfontein gold mining village near Johannesburg, a few hundred F.W.J. 20 mA magamp earth leakage protection units were installed in the homes of the mining village during 1957 and 1958. F.W.J. Electrical Industries, which later changed its name to FW Electrical Industries, continued to manufacture 20 mA single phase and three phase magamp units.

At the time that he worked on the magamp, Rubin also considered using transistors in this application, but concluded that the early transistors then available were too unreliable. However, with the advent of improved transistors, the company that he worked for and other companies later produced transistorized versions of earth leakage protection.

In 1961, Charles F. Dalziel, working with Rucker Manufacturing Co., developed a transistorized device for earth leakage protection which became known as a Ground Fault Circuit Interrupter (GFCI), sometimes colloquially shortened to Ground Fault Interrupter (GFI). This name for high-sensitivity earth leakage protection is still in common use in the U.S.A.[2][3][4][5][6]

In the early 1970s most GFCI devices were of the circuit breaker type. However the most commonly used in the USA since the early 1980s are built into outlet receptacles. The problem with those of the circuit breaker type was that of many false trips due to the poor alternating current characteristics of 120 volt insulations, especially in circuits having longer cable lengths. So much current leaked along the length of the conductors' insulation that the breaker might trip with the slightest increase of current imbalance.

Types

A Residual Current Breaker with Overload (RCBO) is a combination of an RCD and a miniature circuit breaker (MCB).

In Europe RCDs can fit on the same DIN rail as the MCBs, however the busbar arrangements in consumer units and distribution boards can make it awkward to use them in this way. If it is desired to protect an individual circuit an RCBO (Residual-current Circuit Breaker with Overcurrent protection) can be used. This incorporates an RCD and a miniature circuit breaker in one device.

It is common to install an RCD in a consumer unit in what is known as a split load configuration where one group of circuits is just on the main switch (or time delay RCD in the case of a TT earth) and another group is on the RCD.

Electrical plugs which incorporate an RCD are sometimes installed on appliances which might be considered to pose a particular safety hazard, for example long extension leads which might be used outdoors or garden equipment or hair dryers which may be used near a tub or sink. Occasionally an in-line RCD may be used to serve a similar function to one in a plug. By putting the RCD in the extension lead you provide protection at whatever outlet is used even if the building has old wiring.

Electrical sockets with included RCDs are becoming common. In the U.S. these are required by law in wet areas (See National Electrical Code (US) for details.)

In North America, RCD ("GFCI") sockets are usually of the decora size (a size that harmonizes outlets and switches, so that there is no difference in size between an outlet cover and a switch cover). For example, using the decora size outlets, RCD outlets can be mixed with regular outlets or with switches in a multigang box with a standard cover plate.

Active/passive latching/non-latching

RCDs may be obtained that have different behaviours if the circuit they are protecting is de-energised.

- One type will trip on power failure and not re-make the circuit when the circuit is re-energised. This type is known as non-latching. [7]

- Another type will maintain the circuit after power is restored. This type is known as latching or active.

The first type is used when the power-drawing equipment is regarded as a safety hazard if it is unexpectedly re-energised after a power failure e.g. lawn-mowers and hedge trimmers.

The second type may be used on equipment where unexpected re-energisation after a power failure is not a hazard. An example may be the use of an RCD on a circuit providing power to a food freezer, where having to reset an RCD after a power failure may be inconvenient.

Main characteristics

Number of poles

RCDs may comprise two poles for use on single phase supplies (two current paths), three poles for use on three phase supplies (three current paths) or four poles for use on three phase & neutral supplies (four current paths).

Rated current

The rated current of an RCD is chosen according to the maximum sustained load current it will carry (if the RCD is connected in series with, and downstream of a circuit-breaker, the rated current of both items shall be the same).

Sensitivity

RCD sensitivity is expressed as the rated residual operating current, noted IΔn. Preferred values have been defined by the IEC, thus making it possible to divide RCDs into three groups according to their IΔn value.

- High sensitivity (HS): 6 – 10 – 30 mA (for direct-contact / life injury protection)

- Medium sensitivity (MS): 100 – 300 – 500 – 1000 mA (for fire protection)

- Low sensitivity (LS): 3 – 10 – 30 A (typically for protection of machines)

Type

Standard IEC 60755 (General requirements for residual current operated protective devices) defines three types of RCD depending on the characteristics of the fault current.

- Type AC: RCD for which tripping is ensured for residual sinusoidal alternating currents

- Type A: RCD for which tripping is ensured

- for residual sinusoidal alternating currents

- for residual pulsating direct currents

- for residual pulsating direct currents superimposed by a smooth direct current of 0.006 A, with or without phase-angle control, independent of the polarity

- Type B: RCD for which tripping is ensured

- as for type A

- for residual sinusoidal currents up to 1000 Hz

- for residual sinusoidal currents superposed by a pure direct current

- for pulsating direct currents superposed by a pure direct current

- for residual currents which may result from rectifying circuits

- three pulse star connection or six pulse bridge connection

- two pulse bridge connection line-to-line with or without phase-angle monitoring, independently of the polarity

Break time

There are two groups of devices:

- G (general use) for instantaneous RCDs (i.e. without a time delay)

- Minimum break time: immediate

- Maximum break time: 200 ms for 1x IΔn, 150 ms for 2x IΔn, and 40 ms for 5x IΔn

- S (selective) or T (time delayed) for RCDs with a short time delay (typically used in circuits containing surge suppressors)

- Minimum break time: 130 ms for 1x IΔn, 60 ms for 2x IΔn, and 50 ms for 5x IΔn

- Maximum break time: 500 ms for 1x IΔn, 200 ms for 2x IΔn, and 150 ms for 5x IΔn

Surge current resistance

The surge current refers to the peak current an RCD is designed to withstand using a test impulse of specified characteristics ( an 8/20 µs impulse, named after the time constants of the rise and fall of current).

The IEC 61008 and IEC 61009 standards impose the use of a 0.5 µs/ 100 kHz damped oscillator wave (ring wave) to test the ability of residual current protection devices to withstand operational discharges with a peak current equal to 200 A. With regard to atmospheric discharges, IEC 61008 and 61009 standards establish the 8/20 µs surge current test with 3000 A peak current but limit the requirement to RCDs classified as Selective.

See also

- Arc-fault circuit interrupter

- Domestic AC power plugs and sockets

- Earth leakage circuit breaker

- Insulation Monitoring Device

References

- ↑ "GFCIs Fact Sheet". US Consumer Product Safety Commission. http://www.cpsc.gov/cpscpub/pubs/99.html. Retrieved 2009-06-28.

- ↑ Charles F. Dalziel, Transistorized ground-fault interrupter reduces shock hazard, IEEE Spectrum, January 1970

- ↑ The Professional Engineer, Official Journal of the Federation of Societies of Professional Engineers of South Africa, pp 67, Vol 6(2) 1977

- ↑ Earl W. Roberts, Overcurrents and Undercurrents – All about GFCIs: Electrical Safety Advances through Electronics, Mystic Publications, Mystic CT, 1996

- ↑ Edward L. Owen, Power System Grounding Part II: RCD & GFCI, IEEE Industry Applications Magazine, July/August 1996

- ↑ Forging ahead: South Africa’s Pioneering Engineers, G R Bozzoli, Witwatersrand University Press, 1997

- ↑ http://www.floorwarmingcompany.co.uk/pdfs/rcd10wl.pdf RCD brochure, retrieved 2010 Aug 31

External links

- More detail on RCDs from Electricians Toolbox

- Example Electrical Safety Policy (University of Edinburgh)

- Troubleshooting US/Canadian GFCI/GFI devices

- GFCIs Fact Sheet (Consumer Product Safety Commission)

- GFCI Codes and Repair techniques (Hi Lo Electric Inc)

- GFCI Safety Video - What you need to know to keep you safe.